Steel products

-

-

Alloy 718

Nickel Alloy 718, also known as Inconel 718®, is a precipitation hardenable/corrosion and heat-resistant nickel alloy with excellent tensile and impact strength at extreme temperatures from cryogenic environment up to 1300℉/704℃.

Please feel free to contact us by phone.

- Applications

-

- Aviation: Jet Engine Components / Rocket Motors / Fasteners / Thrust Reversers

- Gas Turbine Components

- Cryogenic Storage Tanks - Applicable specifications

-

UNS: N07718

AMS5662: Solution treated / Precipitation-Hardenable bars, forgings, and rings.

AMS5663: Solution and Precipitation Heat Treated bars, forgings, and rings

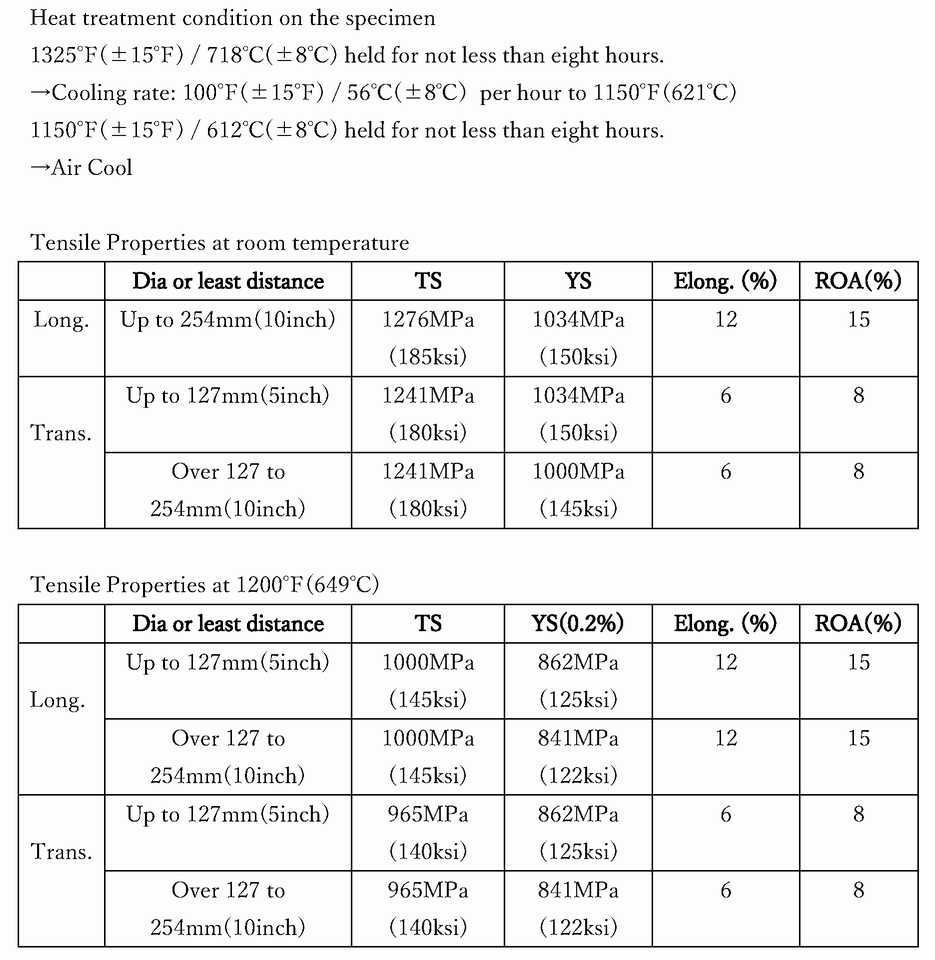

AMS5596: Sheet, Strip and Plate (Annealed)Alloy 718 C Mn Si P S Cr Ni Mo Nb Ti Ingredient values ≦0.08 ≦0.35 ≦0.35 ≦0.015 ≦0.015 17.00~21.00 50.00~55.00 2.80~3.30 4.75~5.50 0.65~1.15 - Mechanical Properties

-

- Hardness at Solution Treated Condition≦277HB(AMS5662)

- Hardness at Aged Condition≧331HB or equivalent(AMS5663)

- Response to heat treatmenthardness(HB) ≦277

- Processability and characteristics

-

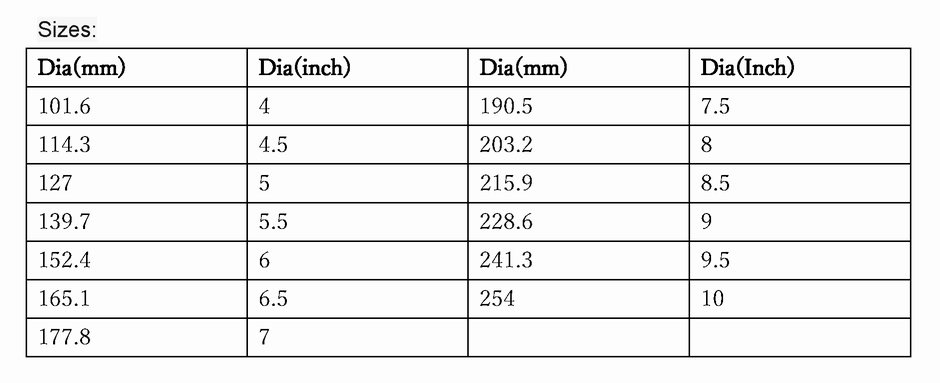

Our Stock Portfolio:

Applicable Specifications:

AMS5662/AMS5663 Capable of/B50TF15(Chemistry Only)/C50TF13(Chemistry Only)

ASME SB637/ASTM B637/UNS N07718

RR9000/SABRe/GE-S-400(S-Spec-35)/GE-S-1000(S-Spec-35-1)

Cert In accordance with EN 10204 3.1 -

Please feel free to contact us by phone.

Disclaimer

However, it is possible that incorrect information may be displayed due to input errors, programming errors, translation errors, etc.,

and we do not guarantee the content of the information (which applies to all forms of provision, including technical and standard materials and inventory materials).

HANSHIN metalics Co., Ltd. will not be held responsible for any damages caused by the use or viewing of this website.