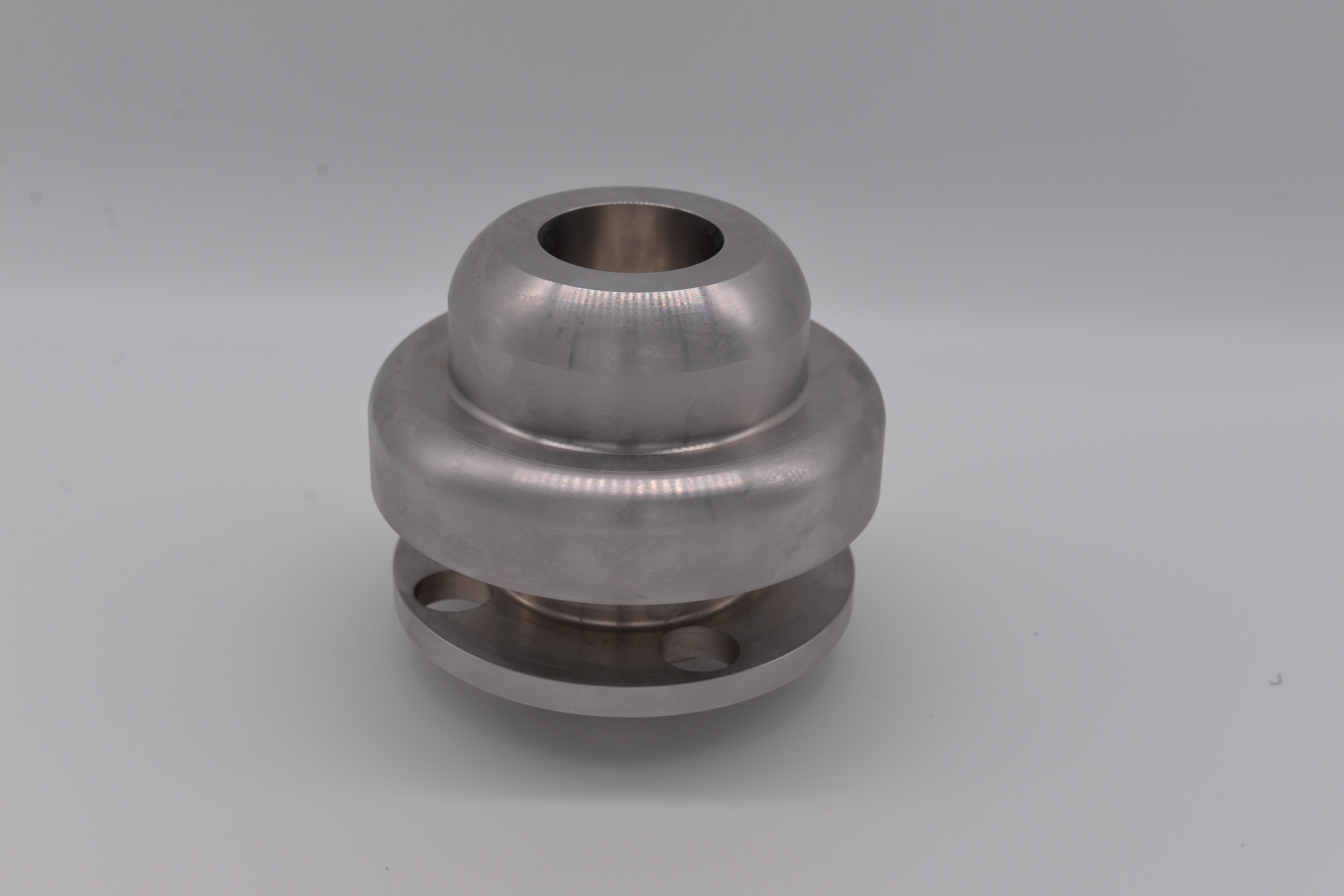

Steel products

-

-

SUS304

SUS304 is an austenitic stainless steel specified in JIS G 4303 "Stainless Steel Bar". It is the most popular type of stainless steel, and is sometimes called "18-8 stainless steel" because it contains 18% chromium (Cr) and 8% nickel (Ni). SUS304 is resistant to rust and corrosion, including corrosion resistance in air, acid resistance, pitting corrosion resistance, and crevice corrosion resistance. It also has high-temperature strength, high-temperature oxidation, high-temperature sulfurization, low-temperature strength, and low-temperature toughness, which maintain heat resistance and strength in both high-temperature and cryogenic environments. The hardness of Type 304 is HB: 187 or less in solution heat-treated condition. Specific gravity is 7.93.

Translated with www.DeepL.com/Translator (free version)

Please feel free to contact us by phone.

- Applications

- Food equipment, general chemical equipment, nuclear power, construction, home appliances, automotive parts, etc.

- Applicable specifications

-

SUS304 is an austenitic stainless steel containing chromium (Cr) of 18.00~20.00, nickel (Ni) of 8.00~10.50, and carbon content (C) of less than 0.080. It is sometimes referred to as 18Cr-8Ni stainless steel.

SUS304 C Si Mn P S Ni Cr Ingredient values 0.08 or less 1.00 or less 2.00 or less 0.045 or less 0.030 or less 8.00~10.50 16.00~18.00 - Mechanical Properties

-

The mechanical properties of SUS304 in its solution heat treatment state are: hardness (HB): 187 or less, proof strength: 205N/㎟ or more, tensile strength: 520N/㎟ or more, elongation: 40% or more, drawing: 60% or more.

Endurance N/mm2 Tensile strength N/mm2 growth % aperture % hardness(HB) Over 205 Over 520 Over 40 Over 60 187 or less - Processability and characteristics

- Compared to carbon steel, SUS304 is difficult to cut due to its viscosity, etc. However, when compared to stainless steel, SUS304 is the most common material, and is probably the most common among stainless steels. For high-precision parts, SUS303 with sulfur (S) added to improve free-cutting properties is used.

Processing examples

Please feel free to contact us by phone.

Disclaimer

However, it is possible that incorrect information may be displayed due to input errors, programming errors, translation errors, etc.,

and we do not guarantee the content of the information (which applies to all forms of provision, including technical and standard materials and inventory materials).

HANSHIN metalics Co., Ltd. will not be held responsible for any damages caused by the use or viewing of this website.